-

Call

+91 98765 12345

-

Email

info@example.com

-

Address

Thane West, Mumbai, Maharastra

- Comprehensive Solutions for Process Control Excellence !

Our Projects

We have undertaken various Custom Designed Skid Projects for our various Clients – to name a few like, Ferring Therapeutics Pvt. Ltd, Owens Corning, Asian Paints, BARC, Nelson Automotive Plant whose summary is as shown below.

All the projects were implemented within the Budget and the Schedule. The Clients were very happy to get Quality products at a very competitive price.

Ferring Therapeutics Pvt. Ltd.

Ferring Therapeutics has set up EOU at Ambernath Thane for API production. The Plant manufacture setup is US FDA approved. Prathit Automation has developed design documents using Smart Plant Instrumentation software, Validation documents for FDA validation as per the pharmaceuticals plant requirement. Also supported project team in Installation and Commissioning of plant.

As a part of validation requirement M/s Ferring has predefined calibration schedule for various instruments on parodic interval. The calibration activity involved large number of sophisticated Flow instruments apart from other process instruments. Wet calibration of instruments was time consuming and expensive, as involved sending of instruments to various labs and reinstalling in plant. Thus, the time consumed in the activity hamper the production scheduling.

Apex Instruments and Control has provided complete calibration support for all process instruments. The flow metering skid for wet calibration of flow instruments was designed, manufactured, and supplied to M/s Ferring. The skid is equipped for calibration of all types of flow meters on site (Liquid) by comparison method, with master flow meters of accuracy 0.05%. This gives major flexibility in production scheduling and adhering to statutory requirement.

Flow Skid

| Calibration of meters from | ½” to 3” meter size |

| Master Flow Meter Accuracy | 0.05% |

| Pumping Capacity | 33 m3/hr |

| Supply | 415 V AC |

Owens Corning

The company is a world leader in Insulation and Roofing systems and composite solutions, delivering a broad range of high-quality products. Owens Cornings products range from insulation, roofing shingles used in residential, commercial, and industrial applications, to glass composite materials used in transportation, electronics, marine, wind energy and other high-performance markets.

For Owens Corning expansion project involved both new machines as well as existing Roving system machines with safety upgradation as per current requirements. The safety upgradation of Roving system with door safety Automation, was done with safety components like Guard safety relay (ABB Vital 1), safety monitor module (Schmersal AZR 31S1), guard release and lock switch, Safety contactor model no:- AFS09-30-22-11 3.7KW, 3 phase 415 V.

Rap Real Safety System upgradation with safety components like Light Curtain (Orion 1) Transmitter & receiver model no. ORION 1-4-30-105B, Safety door sensor – Safe slide with Adam & Eva (Adam OSSD – M12-8 model no. 2TLA020051R5700, Eva General code 2TLA020046R0800, Safety relay model no. SSR10 24VDC, Safety contactor model no. AFS09-30-22-11, Push Button 1 NO/NC contact.

Asian Paints

Flow skid for wet calibration of flow instruments was designed, manufactured, and supplied to M/s Asian Paints. The skid is equipped for calibration of all types of flow meters on site (Liquid) by comparison method, with master flow meters of accuracy 0.05%. This gives major flexibility in production scheduling and adhering to statutory requirement.

Flow Skid

Automatic Flow Skid with PLC and VFD controls. The software suite provided with the system has the provision for storing the complete data base of the instruments used the manufacturing facility. The devise information like make, model no, Instrument Range, calibration date, calibration due date, accuracy etc is stored in the software data base.

The device information is automatically retrieved with Tag number during the calibration process. The technician can perform the calibration check by following the simple calibration steps in the software provided. On completion the tests the 5 point calibration report is automatically generated for records.

| Calibration of meters from | ½” to 3” meter size |

| Master Flow Meter Accuracy | 0.05% |

| Pumping Capacity | 45 m3/hr |

| Supply | 415 V AC |

BARC

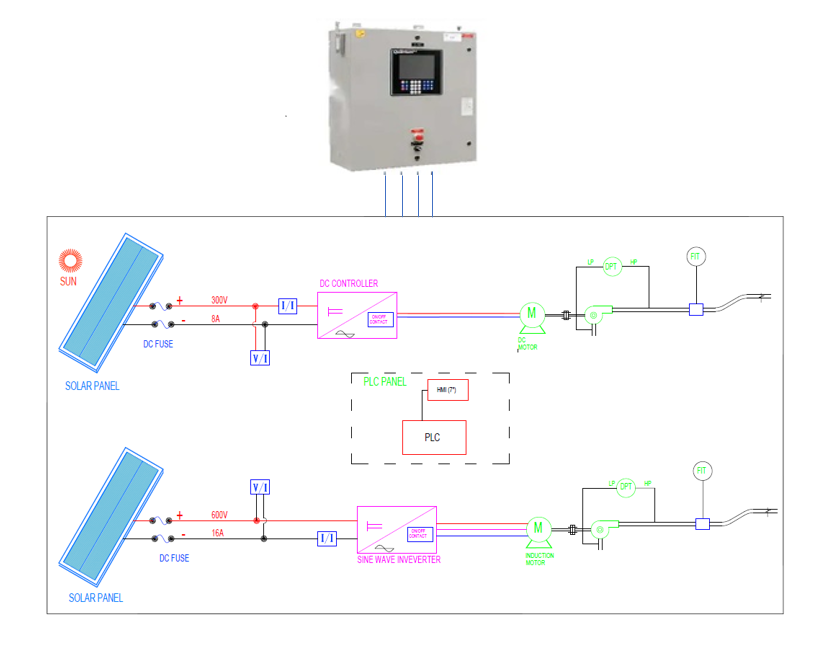

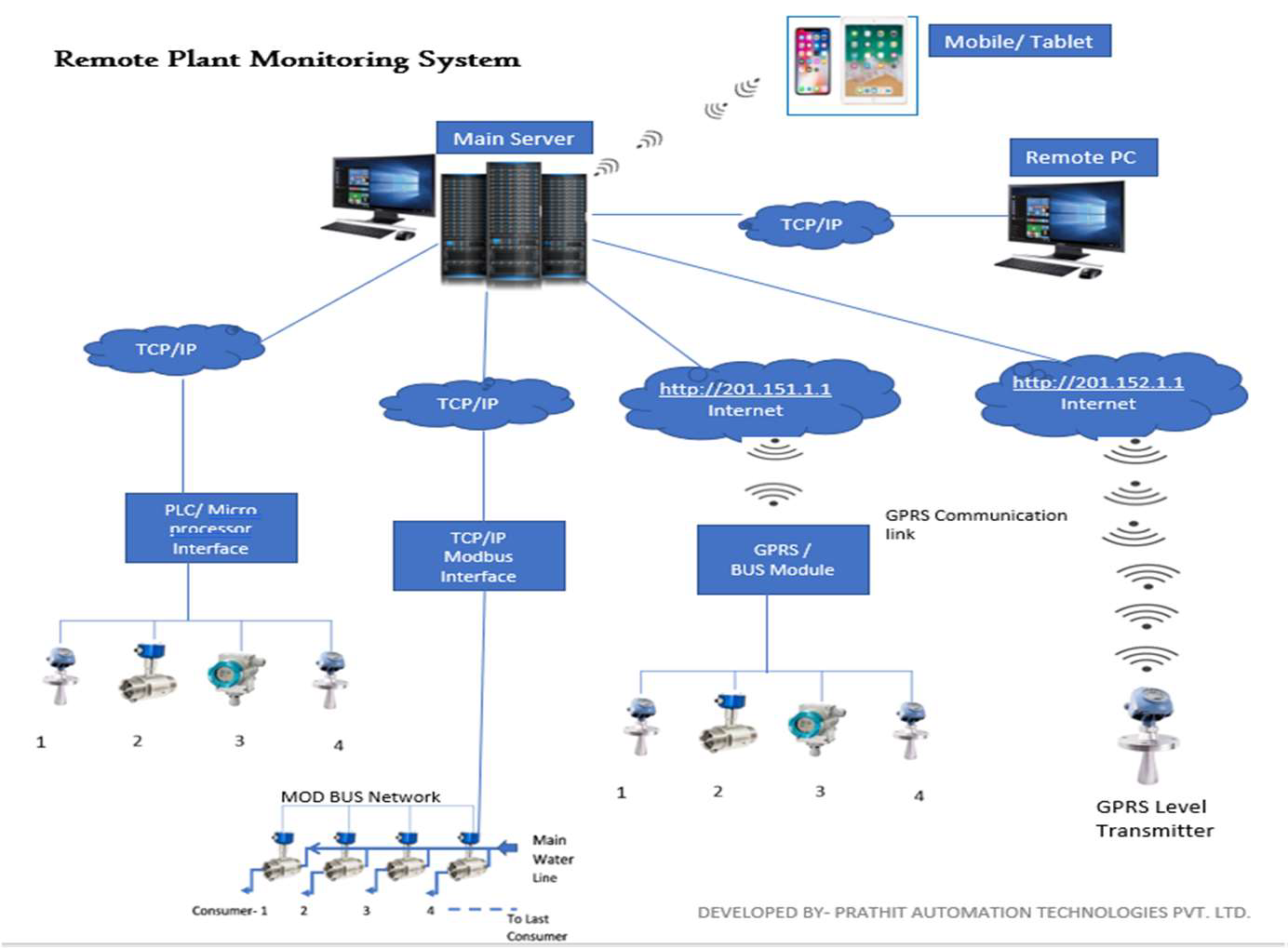

We have undertaken PLC based solar pump automation and monitoring system at BARC. The system consists of PLC based Automation of Solar operated pump and normal electrical supply pump.

Various parameters like pump current, pump voltage, On/Off timing, differential pressure across pump and pump flow rate are monitored for both the systems in the PLC system. All parameters are stored in memory card for further analysis. Various reports are developed for analysis of the data collected. System has features for Typical block diagram for the solar pump monitoring system.

Thermal mass Flow meter for Steel/ Automotive/ Cement Industry

Steel Authority Of India (Bokaro)

We have successfully designed, manufactured, supplied and commissioned IOT based Flow metering system for BF, CO and mixed Gas. The initial order includes measurement at 12 points spread over the area of 50 kms. The system supplied comprises of the state-of-the-art IOT based flow instruments like Thermal Mass Flow meters, Pitot Tube flow sensors etc.

The customized digital monitoring system which has been designed and manufactured by Apex Instruments and Control consists of dedicated controllers, communication based on MQTT through SIM. The user-friendly proprietary software has been developed by our Apex team.

The system is available as CLOUD based or onsite server-based option as per client’s requirements.

Vedanta Steel

We have successfully received the order for the measurement of LD Gas which is the mixture of different gases (CO - 86%, CO2 - 10%, N2 # 3.5%, O2 # 0.5%) from Vedanta Steel. The composition varies depending upon fuel composition. Result in variation of gas composition varies the density of the media. Our Thermal Mass Flowmeter having in build Density Factor Correction with user friendly operation. The features of Thermal Mass Flowmeters make best suited for the low Pressure/ Low Velocity application.

Nelson Automotive Plant

We have successfully installed Air Flow measurement systems in Engine Intake Air conditioning system in Nelson Automotive Plant for the monitoring of Flow, Pressure & temperature through PLC, thermal mass flow system improves the stability and the repeatability of measuring results at combustion engines. The range of parameters depend on the Engine Capacity. Considering the wide range of Air Flow, Temperature and Pressure variation, the unique feature of Our Thermal Mass Flow meter i.e wide flow range of 0.5 to 100m/s. & also the measurement working principle is Independent in Temperature and Pressure variation, makes Thermal mass flow meter best choice for this application.